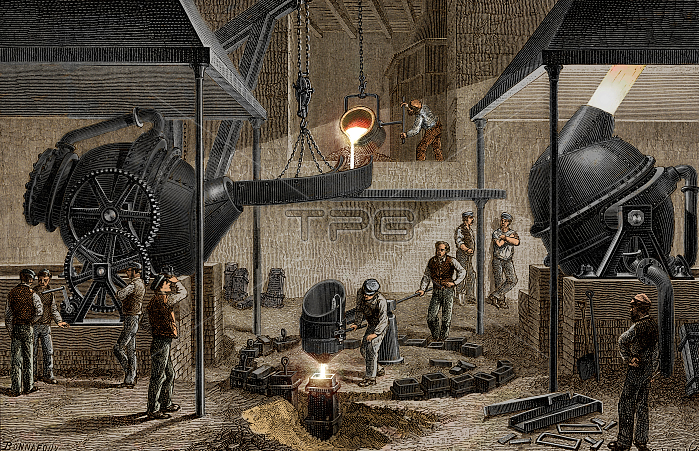

Bessemer Converters turning iron into high-quality steel. The converter on the left is tilted and receiving a charge of molten pig-iron from above. On the right, in the other -now upright- converter, air is being injected through the molten iron raising its temperature to remove the carbon, silicon and manganese impurities and is emitting a blast of fiery gas through the top. When the conversion is complete, the molten steel will be poured into a container and then emptied into moulds for ingots etc, as in the centre of this image. The Bessemer process takes between 10 and 20 minutes to convert 3 to 5 tons of iron into steel. The traditional method took at least a full day. The first inexpensive industrial process for the mass-production of steel from molten pig iron was developed by the British inventor Henry Bessemer in the 1850s, ahead of an American competitor, William Kelly.

| px | px | dpi | = | cm | x | cm | = | MB |

Details

Creative#:

TOP26032890

Source:

達志影像

Authorization Type:

RM

Release Information:

須由TPG 完整授權

Model Release:

No

Property Release:

No

Right to Privacy:

No

Same folder images:

Loading

Loading